Home » Products » Enameled conductors » Thervest Enameled flat wire

Conductors for automotive

Enameled conductors

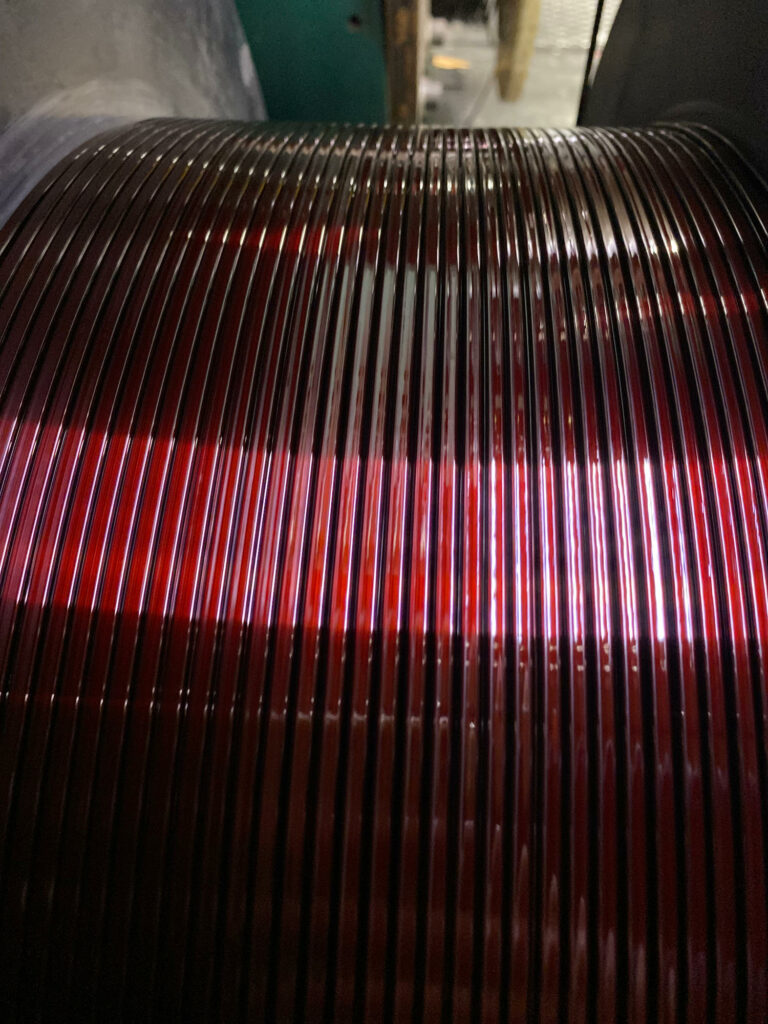

Thervest Enameled flat wire

A wide range of enamelled wires, a product that boasts a thirty-year tradition of production and now adapted to meet automotive needs

Introduction

In the panorama of the automotive industry, De Angeli Prodotti presents its line of enamelled flat wires, a product that boasts a thirty-year tradition of production, initially conceived for the energy market and now adapted to meet automotive needs.

Engineering

Thervest enameled flat wires have a good to very high thermal rating reaching 200 to 240°C.

| ENAMELLED FLAT WIRE | |||

| PEI + PAI | PAI | PI | |

| SURFACE | ••• | ••• | ••• |

| THERMAL CLASS (°C) | 200 | 220 | 240 |

| MAX INSULATION THICKNESS (μm) | 120 | 100 | 90 |

| FLEXIBILITY FOR HAIRPIN PRODUCTION | ••• | ••• | ••• |

| ELECTRICAL PROPERTIES (PDIV, BDV) | ••• | ••• | ••••• |

| CORONA RESISTANCE | • | • | ••••• |

| ATF OIL RESISTANCE | ••• | ••• | ••••• |

Advantages

Thervest enamelled flat wires represent a consolidated solution that we continue to offer with the aim of satisfying the needs of a significant part of OEMs and Tier 1s.

Thanks to their easy workability and competitive price, we believe that this product maintains its relevance in the sector. Our long experience in the production of enameled flat wires allows us to offer a reliable and consolidated product, adapted to the specific needs of the automotive sector.

Furthermore, for those looking for high performance, we present the Thervest 240 enameled with Polyimide. Polyimide is known for its low dielectric permittivity (see table below), especially at high temperatures. This distinctive feature makes the Thervest 240 flat wire particularly suitable for tackling advanced challenges, offering maximum performance in terms of resistance to partial discharges and general dielectric behaviour.