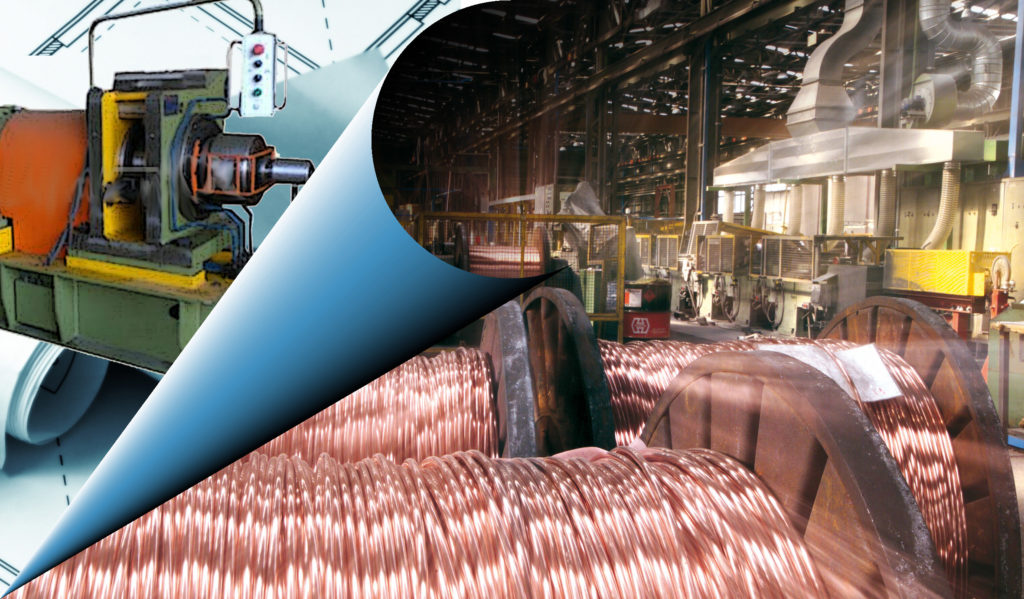

With the new TLJ300 extruder we will guarantee a quality product and a wider range in terms of semi-finished products.

The De Angeli Prodotti’s policy is pushed towards a Lean production system, focused on the theme of efficiency and on optimizing production flow, production processes, and reducing waste. The company philosophy and continuous improvement have led to invest in a new extrusion plant dedicated to the production of copper and aluminum flat wires.

The new extrusion machine TLJ300 has the task of ensuring a quality product and a wider range in terms of semi-finished production both for enamelling department and for the taping department, going to optimize production processes in terms of:

- time (increased productivity with less wasted time)

- supplementary processing (a wider range and more of production flow options)

This reduces the delivery time to the customer, allowing De Angeli Prodotti to deal with quality specifications and more and more restrictive standards.