Litz wires are designed to be used in high frequency applications. But what are their advantages?

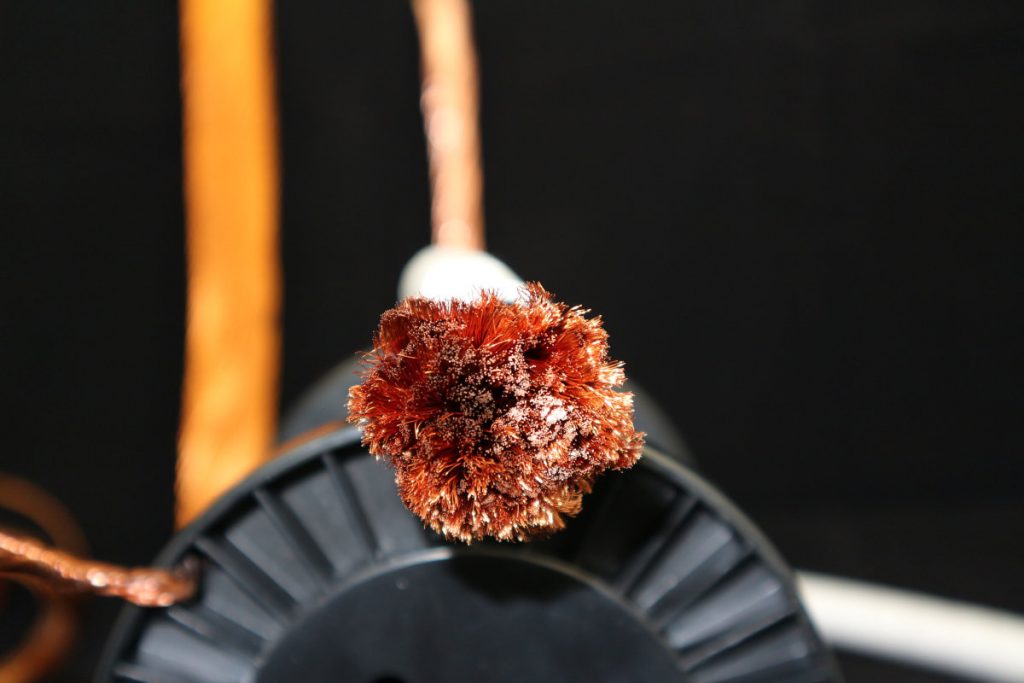

High frequency applications are increasingly widespread in the world of power electronics, their use greatly reduces the dimensions. Litz cables (or Litz wires) fulfill this purpose perfectly. They consist of many strands of thin enamelled round wires, which are twisted and intertwined with each other.

The intertwining of hundreds or thousands of elementary conductors isolated from each other so this eliminates the skin effect and to work very well at frequencies up to 1 MHz.

What is the skin effect?

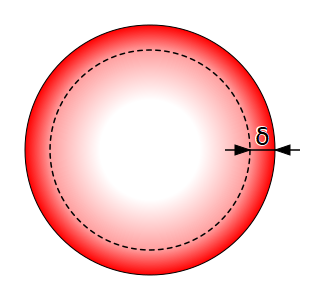

The skin effect is a typical phenomenon of alternating electric current that tends to be distributed more on the surface of the conductor than inside it.

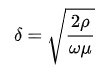

The thickness, starting from the surface, in which most of the current flows is called skin depth, identified by the Greek letter δ.

Skin depth is expressed with the relation:

with ω = 2πf

As can be seen, the value of δ is directly proportional to the resistivity of the material ρ, but inversely proportional to the frequency f. This means that as the frequency increases, the skin depth decreases, so the current will flow in an increasingly smaller section.

A part of the conductor is therefore not used, which inevitably leads to an increase in resistance R (Ohm’s Second Law) and to a corresponding increase in electrical losses.

The concept behind the Litz cable is very simple: to constitute a stranded wire in which the fundamental units are enamelled wires with a diameter smaller than the skin effect. In this way the Litz wire will not suffer from this phenomenon and the losses in high frequency will be significantly reduced.

Which are the proposals of De Angeli Prodotti?

By now the department has been operating for two years, and the production capacity is increasing more and more. The most typical configurations allow the use of single copper wires with a diameter greater than 0.1mm, enamelled in Solvest or Thervest. This lead to the constitution of a Litz cable wrapped in multiple ways such as Nomex, Polyimide, Polyester, Mica-Glass.

The continuous search for innovation has pushed us to exceptional results: more than 10.000 single round wires, a strong increase in the fill factor and great achievements even in the field of rectangular Litz wire!

Which are the possible applications of Litz wires?

There is a large variety of applications for Litz cables:

- Charging columns

- High frequency transformers

- Inverter for photovoltaic panels

- Synchronous/asynchronous motors for electric or hybrid cars

And many others!