ETP plus allows to reach and maintain inside the transformer high proof stress ensuring excellent electric conductivity.

“More than hardening”

Introduction

High voltage transformers are subject, during their lifetime usage, to mechanical stress caused by internal forces between strips and short circuits.

For extra strength required on machineries with significant electrodynamical solicitation CuAg alloy is preferred. The problem with this solution is the high cost of the silver which consequently raises the conductor cost.

Engineering

De Angeli Prodotti has developed an alternative solution, allowing copper flat wires and transposed cables to reach mechanical properties comparable to CuAg alloy. ETP plus gives you high tensile strength with low decay of mechanical properties during usage. The main characteristic of this technology is the very high proof stress maintained also after the station for long times at high temperatures.

Advantages

Which are the advantages of this technology?

ETP plus allows to reach and maintain inside the transformer high proof stress ensuring excellent electric conductivity.

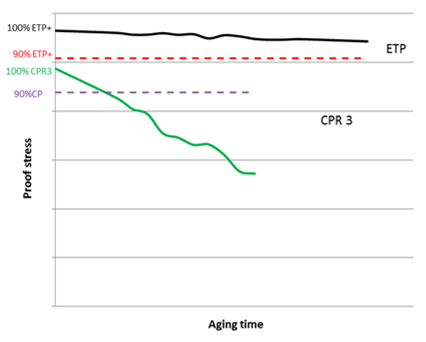

In figure 1 you can see the different decay of mechanical properties between CPR 3 and ETP plus flat wire in an aging test at 220°C.

Conclusions

De Angeli Prodotti has developed an innovative copper flat wires and transposed cables to improve annealing resistance at high temeperature.

This technology allow to obtain transformer more efficient, resistant to short-circuit stress and more economic compared to the current solutions available on the market.