De Angeli Prodotti has developed an innovative cable for railways application, to combat cable copper theft.

“No Copper inside”

Introduction

Generally the conductors used in railway application are composed by copper wires.

The main advantage about copper is on his conductibility, no-one material reach 100% IACS.

The disadvantage to use this material is the costs. The price of copper is very high and this issue make it very attractive for thieves, especially if the conductor is laid down on ground.

Engineering

De Angeli Prodotti and his partner have developed a new technology to avoid the problem with copper.

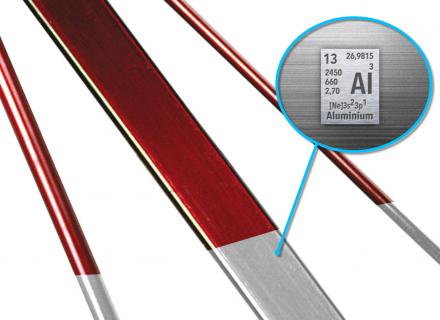

The new design is based on special thermal-resistant aluminium alloy.

A steel wire is covered with an annealed aluminium extruded on it.

A first layer in thermal aluminium alloy with trapezoidal wires and round wires of the same alloy as external layer.

After the stranding phase, the bare conductor is covered with a tape and on it there is a double layer of co-extrude polymer.

Advantages

Which are the advantages of this technology?

The cable is without copper inside and it’s cheaper!

This kind of cable can work at higher temperature than standard copper conductors. Although the aluminium has an higher electrical resistance, this cable can carry the same ampacity.

Conclusions

De Angeli Prodotti has developed an innovative cable for railways application.

This technology is well known for us and the costumer satisfaction for this product is very high!

Up today more than 200 km of cable are already installed and other 500 km will be installed soon!