Introduction

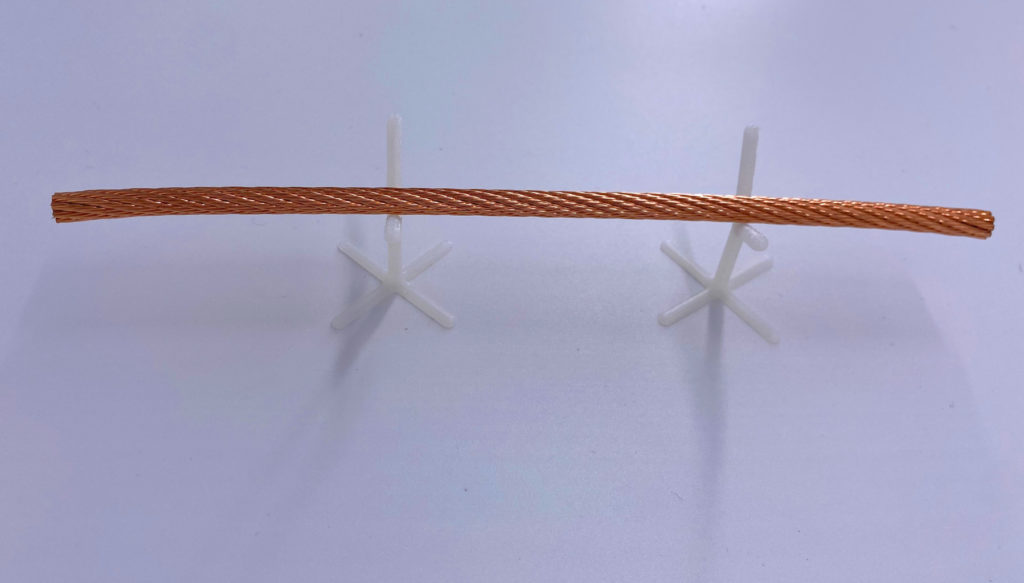

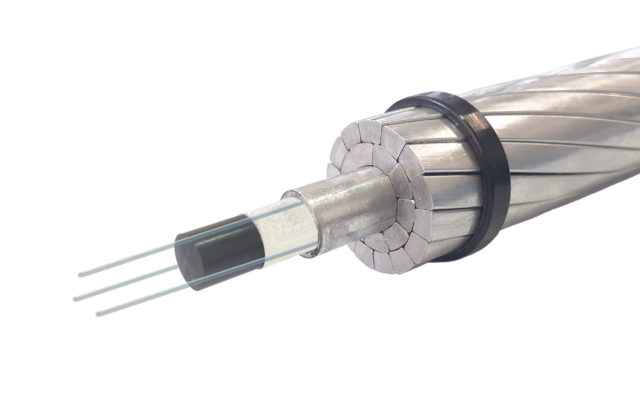

Copper and copper alloy overhead conductors for the electrification of railway lines create a system composed of the feeder, which connects the high voltage network to the railway network and the messenger wire which support, by the dropper wire, the contact wire (trolley).

This system of conductors constitutes the means of the energy transmission from the high voltage grid to the train.

Engineering

De Angeli Prodotti is able to produce according to customer specifications and national and international standards (EN, UNI, DIN, NFC, BS, ASTM) copper and copper alloys (Cu, Cu-Mg, Cu-Ag and Cu-Sn) conductors both concentric and rigid (class 2) and flexible and extra flexible (> class 5, composed of very thin wires) with sections from 10 mm² to 1500 mm².

Advantages

De Angeli Prodotti uses dedicated systems specifically for the production of copper conductors that allow to offer a high production capacity and very long lengths, favoring the efficiency of the installation activity.

Cu-Mg conductors combine the natural conductivity of the copper and the excellent mechanical resistance of magnesium, which create a perfect union of good electrical resistance and high breaking load, perfect for high speed lines (High Speed Train).