Introduction

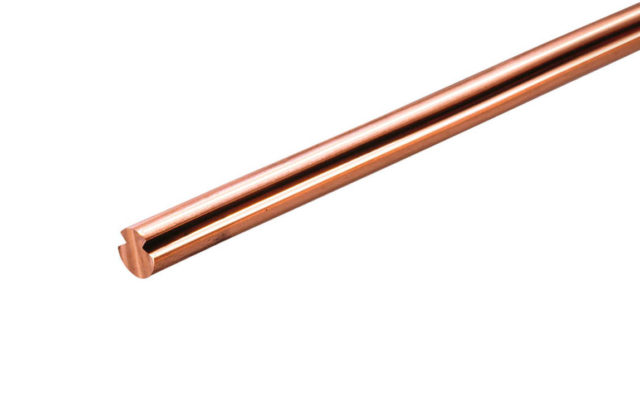

The Gap-Type technology owes its name to the particular geometric conformation, characterized by a space (gap) that separates the core and the external conductive layers.

De Angeli Prodotti produced and supplied more than 2.000 km of Gap-Type.

Engineering

The “gap” between the galvanized steel or ACS (Aluminium Clad Steel) core and the first conductive layer, once filled with thermo-resistant lubricant, allows the core to slide inside the conductor, thus enabling the correct setting of tension and sag.

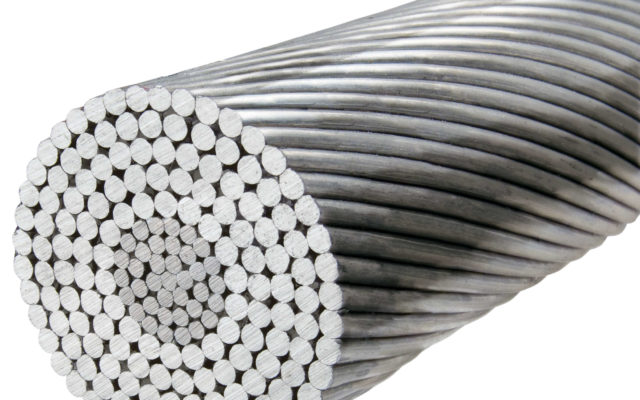

The outer layers are made of trapezoidal or “z” shaped and/or round Thermal Aluminium Alloy Al-Zr wires.

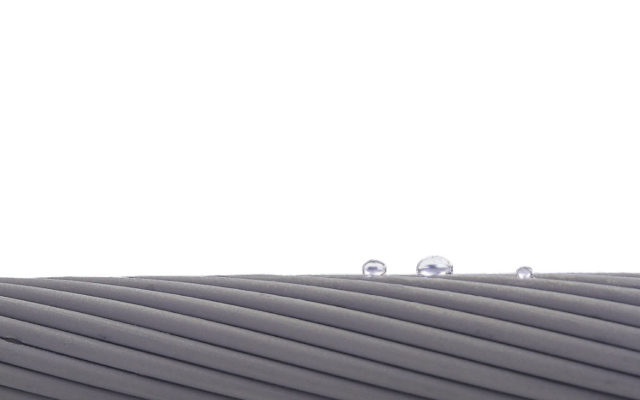

Due to its special geometric configuration, the gap conductor has the limited thermal expansion coefficient of the steel core above stringing temperature, and permits therefore small sag at high operating temperatures (up to 210°). Below stringing temperature the conductor behaves as a standard ACSR conductor.

The aluminium alloy layers contribute to the mechanical characteristics of the gap conductor in heavy load conditions at low temperature, as heavy wind and ice.

The Gap conductor requires a specific installation procedure. A dead-end clamp is compressed on the steel core only, while the aluminium alloy layers are left hanging free. The final compression of the aluminium sleeves is applied after an overnight settlement pause.

De Angeli Prodotti can support a correct execution of all installation activities with training and supervision, thanks to its know-how and experience.

De Angeli Prodotti designs and supplies the complete set of line hardware and accessories, tailor-made for a proper operation of the Gap-Type system, including the special dead-end clamp.

Advantages

Thanks to a specific installation process, the Gap-Type allows to obtain low expansion and excellent results in terms of current capacity increase (Ampacity + 100%), at affordable cost, without modification or reinforcement of the towers.