Introduction

In an electrical winding, the number of turns and the magnetic flux are inversely proportional to the frequency of the current.

High frequency applications are increasingly widespread in the world of power electronics, their use greatly reduces dimensions. Working at higher frequencies means reducing the size of the transformer.

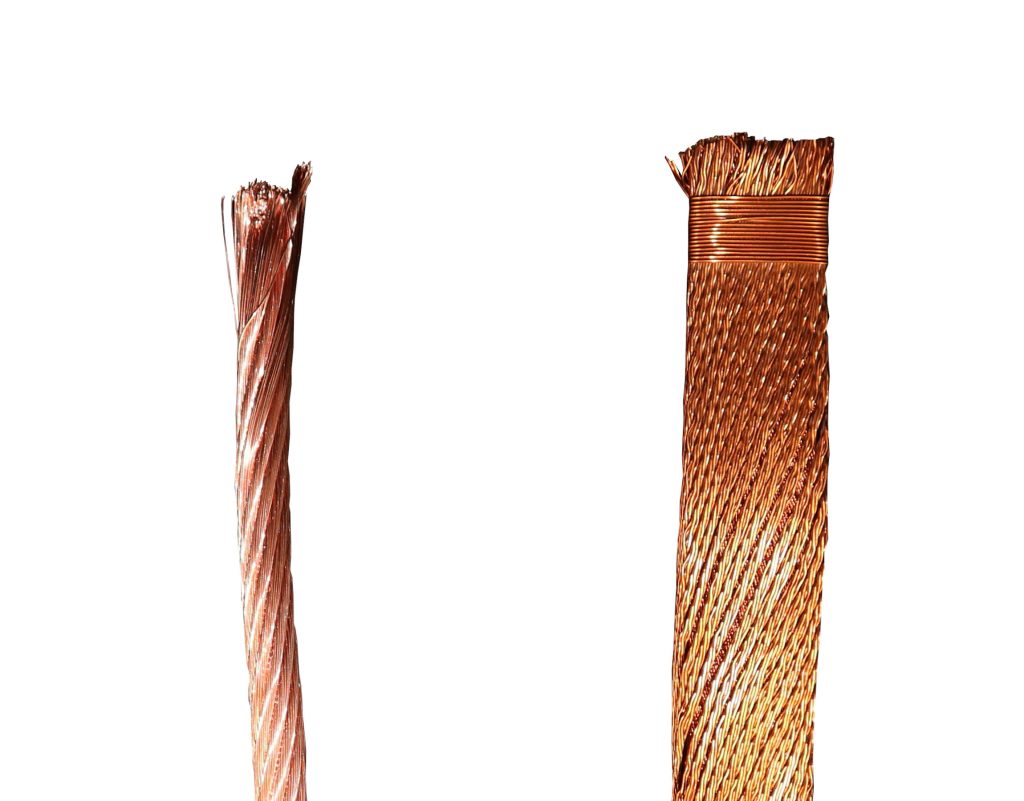

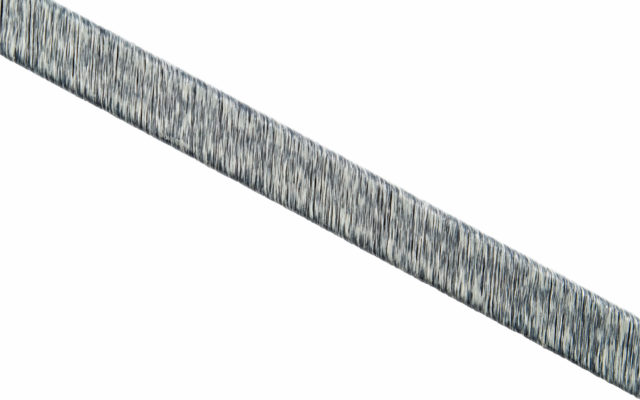

Litz cables (or Litz wires) fulfill this purpose perfectly. Litz wire consist of many strands of thin enamelled round wires, which are twisted and intertwined with each other.

Engineering

Hundreds or thousands of elementary conductors isolated from each other allows to reduce losses in the transmission of alternate current, avoiding the skin effect.

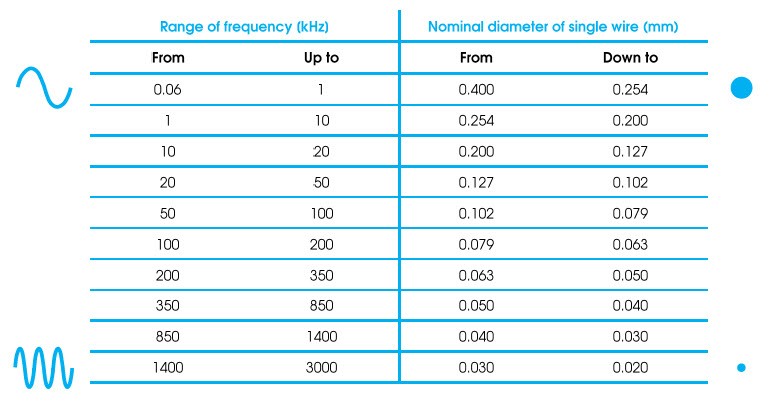

The concept behind the Litz cable is very simple: to constitute a stranded wire in which the fundamental units are enamelled wires with a diameter smaller than the skin effect.

In this way Litz wire will not suffer from this phenomenon and the losses in high frequency will be significantly reduced.

Below is an example of the possible solutions offered by De Angeli Prodotti:

| Individual wire | Material | Spec. Resistance [Ωmm2/m] | Density [Kg/m3] | Diameter [mm] |

| Copper | 0.0171 | 8890 | ≥ 0.05 | |

| Aluminium | 0.0278 | 2700 | ≥ 0.2 | |

| Insulation type for the individual wires | Name | Enamel type | Thermal class [°C] | Solderability |

| Solvest F | PU | 155 | yes | |

| Solvest H | PU | 180 | yes | |

| Thervest/Adhexal | PEI+PAI | 200 | – | |

| Enamel build: Grade 1, Grade 2, Grade 3 | ||||

| External insulation type | Type | Thickness [µm] | ||

| Polyester | 23 | |||

| Nomex T410 | 50 | |||

| Polyimide | 25 – 38 – 50 | |||

| Conductofol | 90 | |||

| Mica-Glass | 100 | |||

| And much more! | – | |||

| Silicone extrusion after taping is possible | ||||

Advantages

Thanks to its extraordinary features, the litz allows to build electrical machines otherwise impossible with a traditional conductor.

The intertwining of hundreds or thousands of elementary conductors isolated from each other so this eliminates the skin effect and to work very well at frequencies up to 1 MHz.

Thanks to its extraordinary features, litz wire offers a revolutionary solution in the realm of electrical engineering, enabling the construction of electrical machines that would otherwise be impossible with traditional conductors. The unique construction of litz wire involves the intertwining of hundreds or even thousands of elementary conductors, each individually insulated from one another. This intricate design effectively eliminates the skin effect, allowing litz wire to perform exceptionally well at frequencies up to 1 MHz.

The key advantage of litz wire lies in its ability to mitigate the skin and proximity effects, phenomena that occur when alternating current flows through a conductor, causing the current to concentrate near the surface. By incorporating numerous wire strands, each insulated wire, litz wire constructions distribute the current more evenly across the cross-sectional area of the wire. This uniform distribution helps to reduce AC losses, particularly in high-frequency applications, where traditional conductors would suffer from increased resistance and inefficiency.

Furthermore, the strands of enameled wire used in litz wire are often twisted or braided into a uniform pattern, further enhancing its performance characteristics. This meticulous construction minimizes electromagnetic interference and optimizes signal integrity, making litz wire an ideal choice for demanding applications such as switching power supplies, transformers, and high-frequency electronic circuits.

Contact us to find the litz wire fitting your needs!

Image Gallery

Download

High Frequency Litz Wire vertical_align_bottomDownload PDF