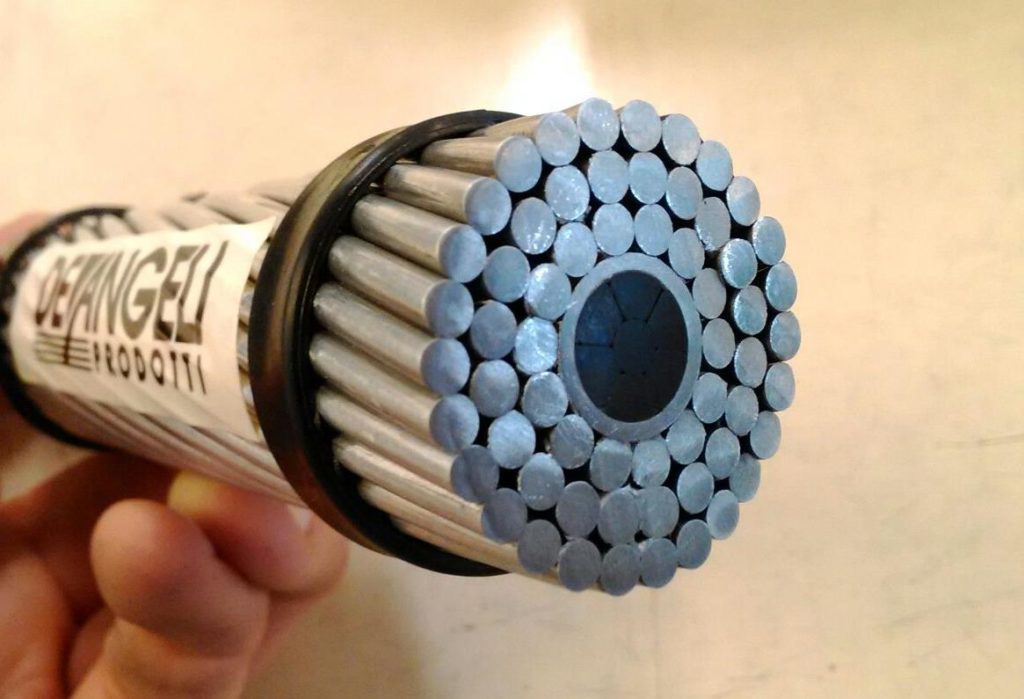

De Angeli Prodotti announces its first trial installation for the innovative Aluminium Conductor Composite Multistrand, called ACCM.

It’s with pleasure that De Angeli Prodotti announces its first trial installation for the innovative Aluminium Conductor Composite Multistrand, called ACCM.

In TERNA’s training field in Viverone a 400 m, triple bundle line was installed with fittings, spacers, joint and dampers simulating all the procedures that will be followed during an installation.

This test occurs after 5 years of intensive work where all the parties involved in this project (the european Best Paths Project) have collaborated together for the same goal: allow TERNA to install in its lines the most modern HTLS conductor with composite core.

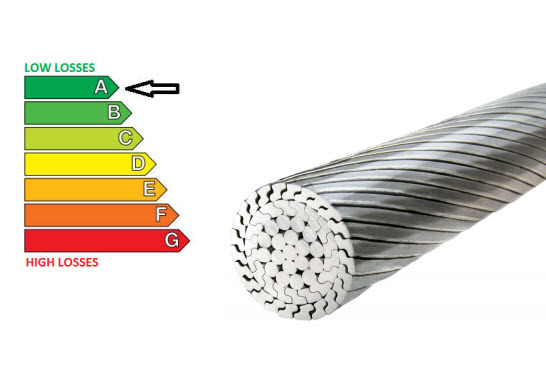

Why a carbon fiber ACCM conductor?

- Because with the carbon core, 7 times lighter than the steel and 3 times stronger we can reduce the sag compared to standard HTLS conductors.

- Because with 7 wires we increase the safety coefficient during the installation and long life of the conductor.

- Because the trapezoidal shape for the carbon wires allows a filling factor of the core more than 90%.

Isn’t it a brilliant solution?!

The people that have taken part in the project were not only coming from De Angeli Prodotti’s technical department but also from Officina Fratelli Bertolotti for the fittings, Powercom for the stringing tool and Elettrodotti Cantamessa for the installation, all coordinated by the Overhead Electrical Lines team of TERNA.