Introduction

The continuous evolution of technologies in the E-Mobility sector is leading car manufacturers to increasingly demanding challenges, with operating voltages that easily exceed 800 V. In this scenario, it is crucial to adopt innovative and cutting-edge solutions to guarantee performance and superior reliability. De Angeli Prodotti’s Polyimide-FEP wrapped flat wires represent a reliable and advanced response to this growing demand in the sector.

Engineering

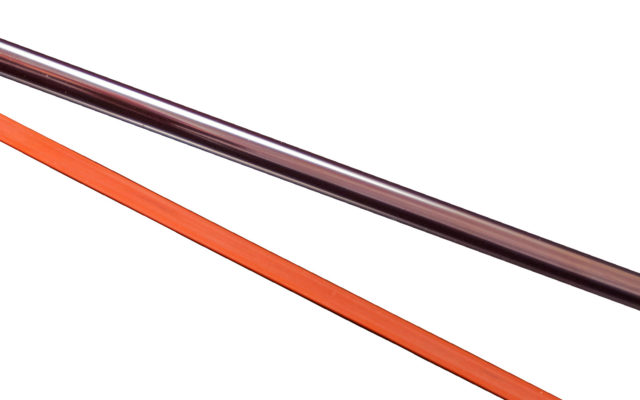

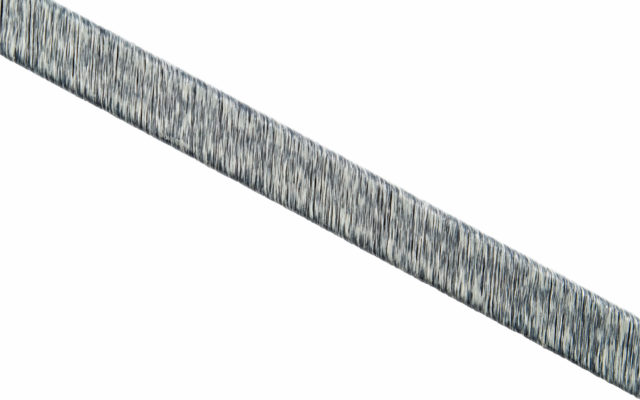

Polyimide FEP wrapped flat wires are specifically designed for the application of polyimide composite tapes with a sintering process.

| WRAPPED FLAT WIRE | |

| ADHESIVE POLYIMIDE | |

| SURFACE | ••••• |

| THERMAL CLASS (°C) | 240 |

| MAX INSULATION THICKNESS (μm) | 200 |

| FLEXIBILITY FOR HAIRPIN PRODUCTION | ••• |

| ELECTRICAL PROPERTIES (PDIV, BDV) | ••••• |

| CORONA RESISTANCE | ••••• |

| ATF OIL RESISTANCE | ••••• |

Advantages

While some concerns have arisen among OEMs/Tier 1s regarding wrapped flat wires, it is important to highlight that this solution offers a number of unique advantages. Thanks to the use of a specific glue during the taping process, we guarantee a strong adhesion to the conductor, allowing the creation of complex configurations such as the hairpin-type bend. This aspect, often a source of concern, is successfully overcome, offering a highly flexible and adaptable solution to project needs.

Furthermore, the Polyimide-FEP wrapped flat wire has one of the highest resistances to partial discharges on the market, comparable to solutions such as PEEK. This attribute, combined with excellent oil compatibility, positions it as an ideal choice for applications where safety and performance are priorities.

De Angeli Prodotti continues to challenge conventions, offering innovative and reliable solutions in the field of E-Mobility. Polyimide-FEP wrapped flat wires represent a step forward, guaranteeing flexibility, safety and high level performance in a constantly evolving sector.