High-performance flat conductors are fundamental elements for the efficiency and reliability of high-performance electric generators and motors, supporting the transition to cleaner energy.

The growing need to decarbonize the energy sector has highlighted the importance of renewable sources and low-impact environmental technologies. In this context, high-performance flat wires play a key role in the design of efficient and reliable electric generators and motors. These are thin and flat cables used for winding high-performance electric generators and motors. They are of crucial importance as they enable a uniform distribution of current flow within rotating machinery, ensuring efficient and reliable operation.

- 1. High-performance flat conductors: what challenges do they solve?

- 2. The main solutions offered by De Angeli Prodotti

- 3. Conclusions

1. High-performance flat conductors: what challenges do they solve?

The transition towards a low-carbon society and the adoption of renewable energy sources are crucial goals to combat climate change. Within the realm of renewable energy technologies, high-performance generators and motors play a fundamental role in clean energy generation. However, the operation of such machines involves high voltages and mechanical stresses, making precise monitoring and the use of advanced materials essential to ensure reliable and safe performance. One of the key components in this context is high-performance flat conductors – thin and flat cables with special insulating coatings – which ensure excellent electrical conduction and insulation, enabling the proper functioning of electric machinery in critical environments.

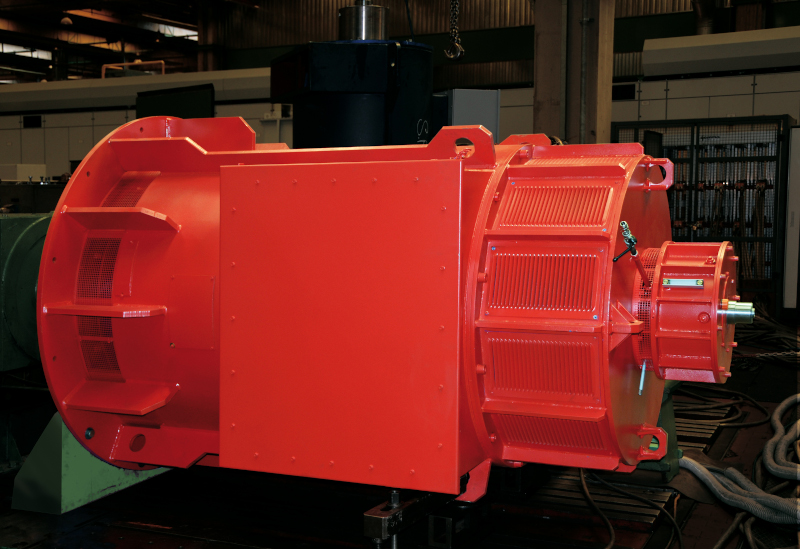

2. The main solutions offered by De Angeli Prodotti

De Angeli Prodotti is a strategic supplier of materials dedicated to the world of high-performance electric generators and motors. In particular, we offer a wide range of specific solutions for the production of high-performance flat conductors, all designed to meet the high standards required by industrial applications and renewable energy sources.

For example, Kapton tapes, which are polyimide-coated conductors, combine remarkable dielectric, chemical, and mechanical properties, providing high thermal and chemical resistance, as well as radiation resistance. Additionally, we produce insulated conductors made of fiberglass, which impart specific mechanical strength, and Mica-coated conductors, known for their excellent mechanical and insulating resistance. These products are well-suited for use in even the most demanding electric machines, offering valuable support to the industry in creating highly efficient and environmentally friendly electric machinery.

2.1 Tape Kapton

They are synthetic polymers used for electrical insulation. Polyimide films and tapes are particularly well-suited for reliable insulation of cables and wires. To achieve insulation, composite materials are created with a polyimide film coated on one or both sides with a fluoropolymer.

These tapes combine electrical and thermal properties, allowing for a wide range of use from -200 to +250 °C. They are used in applications such as traction motors, transformers, and aerospace systems.

Our products are particularly resistant to solvents, acids, and radiation. They are also known for their flexibility, mechanical strength, and dimensional stability.

2.2 Not only Tape Kapton

2.2.1 Fiberglass insulated conductors

These conductors are made using glass or glass-polyester composite yarns, providing high resistance to mechanical stress. They can be produced as either enamel-coated or bare flat conductors, in copper or aluminum. The use of impregnation varnishes such as polyurethane, polyester, or epoxy ensures proper bonding.

2.2.2 Mica insulated conductors

This type of conductor insulation consists of calcinated mica, a polyester or glass support, and impregnating resin. Mica provides excellent dielectric and mechanical properties to the conductor, making it particularly suitable for high-voltage rotating machinery.

3. Conclusions

The use of advanced insulating materials, such as Kapton tape and other specialized products, like those provided by De Angeli Prodotti, has successfully addressed the challenges associated with high voltages and mechanical stresses. Looking to the future, ongoing research and development in this field will further enhance the generation of clean and sustainable energy, promoting a low-carbon future for the benefit of our society and the global environment.