Let's see in detail what HTLS conductors are and what their properties are. The article also includes a recent case study for Elia Belgium

A transmission line is a structure used to carry power or signals over large distances. A transmission line is made up of the structure and the relative cables passing through it. In this case we are talking about high voltage power lines which can be overhead, with an infrastructure made up of pylons (commonly in metal, but also in wood or concrete) and conductors, or underground, with an infrastructure made up of underground pipes (cable ducts where the cables pass. The conductor, therefore, is a fundamental element of the transmission line and must be chosen with particular care and according to criteria of sustainability, economy and performance. In this scenario, HTLS is the acronym that identifies the type.

HTLS stands for High-Temperature Low Sag, it is a conductor capable of not physically deteriorating and maintaining its transmission capabilities intact at higher temperatures than conventional conductors. As it is easy to understand, precisely because of these properties, it is a more expensive conductor to implement on a new line, but it constitutes an economic choice for the modernization of existing lines, as we will see in the final case study which has as object the installation of ACCS-sens De Angeli conductors for Elia, the Belgian TSO.

Summary

1. HTLS conductors

Building a new transmission line does not only have technical and/or economic difficulties: being a work that impacts the environment for tens, sometimes hundreds of km, it involves several actors both at a political and institutional level. Furthermore, finding suitable places for it to pass is not always easy. If one builds an underground line, he may run into difficulties due to the structure of the ground (just think of a rocky layer which can be very expensive to cross or excessive permeability which could lead to stagnation which in the long run would damage the hardware components of the infrastructure). If, on the other hand, an overhead transmission line is built, it is easy to understand how a fundamental interlocutor becomes the body in charge of landscape authorization since the infrastructure of pylons and cables impacts on the natural or urban landscape in which it is located. For this type of transmission line, however, the technical and environmental difficulties remain due, for example, to a changing climate and the unpredictability of an element such as snow load and, although the engineers always work with abundant safety margins , the economy of the works foresees not to presuppose “impossible” scenarios that could all happen in the event of exceptional events that are difficult to predict.

It is easy to understand that, in order to do so, we try to limit the construction of new lines as much as possible and we aim to modernize existing ones to obtain the maximum possible performance in terms of efficiency and safety.

1.1 HTLS conductors: what are they for?

To optimize existing lines it is necessary to ensure that they are able to support an increase in voltage without decreasing their performance. Increasing the voltage means increasing the work the cable has to do to handle it, and this work translates into heat. This heat leads to overheating of the infrastructure which, if it is not suitably prepared, loses effectiveness while rapidly deteriorating. An example? Suppose our old transmission line is a person untrained to run who is walking to get from point A to point B. If we suddenly ask him to run, for sure he can do it, but his body will get hot, sweat , and he will get tired until he stops before the finish line which perhaps he would have reached more slowly, but comfortably, by continuing to walk.

It is clear that an HTLS conductor is a person trained to run, i.e. a thicker or more resistant cable. It is understood that, exactly as happens for a person, even if well trained, he has a threshold beyond which he cannot go fast without getting tired or hurting himself. Therefore, even an HTLS conductor still has maximum limits of use in terms of temperature and stress.

1.2 HTLS conductors: what are they?

The drop in performance mentioned in the previous paragraph actually causes a decrease in the distance they can travel – for example before the presence of a pylon, or an elevation of the pylon itself – if you do not want to increase the number of poles, but both solutions appear not very acceptable from a landscape point of view. In the same way, underground lines, even if they don’t have to bear snow, wind and frost, have another terrible enemy: vibrations (without disturbing a telluric phenomenon we can imagine the proximity of a subway or the passage of a railway line itself) and an increase voltage on unsuitable cables would amplify the damage. HTLS conductors are nothing more than conductors “trained” to withstand the situations of conventional cables, but in situations of higher temperatures. In fact, as we will analyze in the next paragraph, they are “only” cables made with more resistant materials or with a more performing technological development.

2. HTLS conductors: types

Most transmission lines today use aluminum as the main material due to its conductivity and light weight. At most, it reinforces it with steel to increase its resistance to bending even in the case of larger spans. By span we mean the distance that the cable must cover, for example from a pylon A to a pylon B. The cable cannot be tensioned as this would increase its rigidity, weakening it in the presence of loads (for example snow) and cannot nor be too slow as this would cause dangerous oscillations or an unacceptable proximity to other cables in the presence of wind. Therefore it can be said that the conductor must be “as stretched as possible” in the configuration in which it bears atmospheric loads. This result can be added with HTLS conductors chosen for technology, materials and costs.

2.1 Smart conductors

A Smart Conductor is a conductor that consists of a cable composed of a steel and aluminum tube with an optical fiber inside capable of communicating the status of the line (faults, breakages, temperature, vibrations) with predisposed equipment. As it is easy to understand, this real-time monitoring of the transmission line leads to an almost cancellation of outages thanks to targeted maintenance which, in turn, leads to a saving of resources with a consequent reduction in costs.

It is a technology suitable for the modernization of existing lines which allows saving on infrastructural works with a “discount” equal to 75% compared to the cost of a new line.

2.2 Invar core conductors

An Invar Core conductor is an HTLS conductor which consists of a cable composed of an “Invar” iron and nickel alloy interior characterized by a reduced coefficient of thermal expansion, to which conductive mantles in Thermal Aluminum Alloy Al-Zr ( IEC 62004). This is the most widely used technology in the world due to its low cost of installation and its ability to withstand very high voltages.

2.3 Gap-type conductors

A Gap-Type conductor is an HTLS conductor that consists of a conductor with a gap filled with a heat-resistant lubricant that separates the galvanized steel or ACS (Aluminium Clad Steel) core from the outer Thermal Aluminum Alloy conductive layers Al-Zr. It has extraordinary mechanical characteristics even in adverse weather conditions. It is a technology suitable for the modernization of existing lines as it allows to maintain the pylons that already exist, saving on infrastructural works.

2.4 ACSS conductors

An ACSS conductor is an HTLS conductor with a core composed of UHTS high tensile steel wires and protected by a zinc-aluminium tube, while the conductive mantles are made of annealed aluminium. It is a technology suitable for the modernization of existing lines that operate with AAAC conductors which increases the energy flow rate and limits line losses.

2.5 ACCM conductors

An ACCM conductor is an HTLS conductor which consists of a cable composed of a load-bearing core made up of several composite elements in heat-resistant carbon fiber and stranded together. This core is protected by a tape and an aluminum tube which makes it resistant to atmospheric agents. It is the most innovative bare conductor in the world because it combines all the advantages of the previous conductors in a single cable: transmission, robustness, lightness and safety, even if it is less economical than a standard bare conductor in reinforced aluminium.

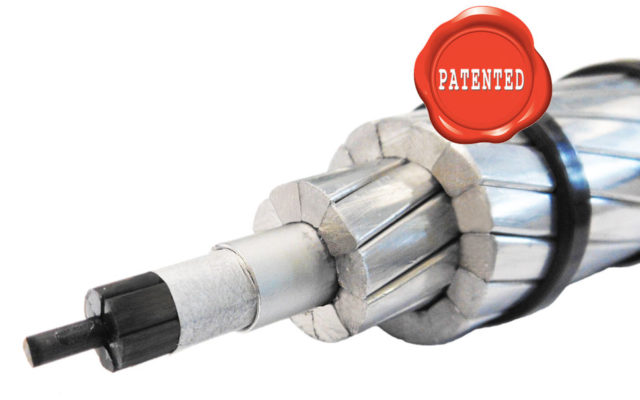

2.6 ACCS conductors

An ACCS conductor is an HTLS conductor formed by a heat-resistant carbon fiber core, covered with a tape and protected by an extruded aluminum tube which makes it resistant to atmospheric agents. It is a conductor with excellent performance in terms of strength, transmission and lightness compared to a standard conductor.

2.7 ACCS-Sens conductors

An ACCS-Sens conductor is an HTLS conductor which consists of the ACCS conductor with inserted optical fibers in direct contact with the carbon core. These have the goal of monitoring the integrity of the core during the production and installation phases.

3. CASE STUDY: De Angeli ACCS Conductor

In order to understand how the use of an HTLS conductor can be useful in the modernization of an existing line we propose the case study of De Angeli for Elia, with 350 km of ACCS-Sens HTLS conductors installed in Belgium between 2021 and 2022 .

3.1 The customer: Elia, the Belgian TSO

Elia is the transmission system operator in Belgium and Germany and is one of the top five TSO operators in Europe with 19,192 km of connections.

3.2 The problem: modernize the current aluminum line

The current line was composed of a conductor entirely made of aluminum alloy. This made it a lighter conductor than other standard steel core conductors and exposed the use of heavy conductors to being a risk. For this reason it was essential to choose a technology with a carbon core: efficient and very light.

3.3 The solution: installation of ACCS-Sens De Angeli Prodotti conductors

After the manufacturing of the ACCS-sens conductors in the factory of De Angeli Prodotti we moved to Belgium for the installation. The installation of 350 km of conductors led to a stranding phase that lasted more than a year which De Angeli Prodotti followed directly on site at all times.

Our presence on site is essential to train the people who deal with the installation of the conductors, in order to be able to carry out a state-of-the-art installation. Not only that: our highly specialized technicians take care of checking all the equipment and instruments used for this purpose in order to maintain the high standards we ask to guarantee the end customer compliance with the reliability and safety requirements we have mentioned.

Conclusion

As we have read in this article, all HTLS conductors represent an excellent solution for modernizing existing transmission lines. Given the constant research that has characterized a growing market aimed at the electric transition, the possibilities are diverse and cover a wide range of problems.

We at De Angeli Prodotti are proud to say that we follow all the phases, from the drafting of the project to the choice of the best solution for the customer, from the creation of the conductors in Italy to their installation.