Paper insulated wires are an excellent solution for both oil and dry transformers. But what are the advantages?

Sometimes it’s good to go back to theory. Do we all remember how a transformer works and how is it made?

A transformer is a static electric machine powered by alternating current, consisting of two decoupled circuits: a primary (input) and a secondary (output). Thanks to the phenomenon of electromagnetic induction, electricity is transferred from the primary to the secondary by changing the voltage and current values.

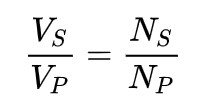

In an ideal transformer, the ratio between the voltage induced in the secondary winding (Vs) and the primary voltage (Vp) is equal to the ratio between the number of turns of the secondary winding (Ns) and the number of turns of the secondary winding (Np), as in the following formula:

By carefully choosing the number of turns, a transformer allows you to increase the voltage on the secondary or decrease it. The typical application is the use of the transformer as a means of interfacing between power trasmission networks at different voltages.

Oil transformers or dry transformers?

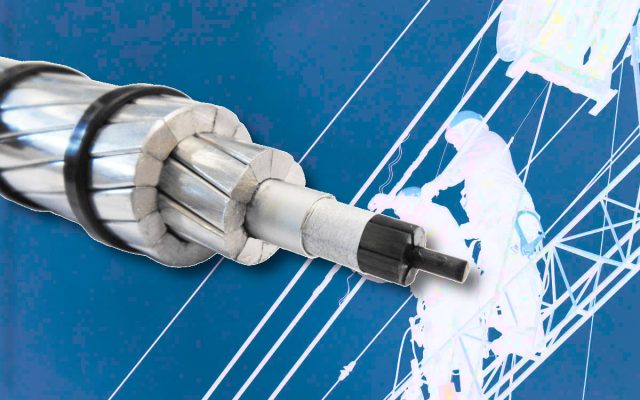

There are two types of transformers:

- oil transformers, in which cooling takes place by means of a mineral oil

- dry transformers, cooling takes place via air or gas.

Opting for one or the other construction is not trivial, the designer will have to carefully consider the type of use and the area where that particular transformer will be installed.

Whatever the choice between the two available, De Angeli Prodotti offers one of the most flexible insulation technologies: taped copper and aluminum wrapped wires!

De Angeli Prodotti offers a wide range of insulation materials!

For oil-filled transformers, the most common insulating paper for windings is pure cellulose Kraft paper which, together with its thermo-stabilized version, represents the optimal solution for this type of machine.

For dry transformers and wherever high performance is needed, taping with alternative materials is available: Aramid, Polyester, Nomex, Polyimide, and many others to meet the demands of all designers.

What are the advantages of our paper wrapped conductors?

Like all our products, they are tailor-made together with our customers. Our technical team will support you in choosing the right materials and arrangements, to ensure the success of your projects.